Gear units

Industrial gear units presentation

Gear unit is the main device of a gearmotor. A gear unit transforms the torque and the speed of a motor mounted upstream. The slow speed and fast speed is therefore one of the most important characteristic values of a gear unit. How powerful a gear unit is and the loads that it can convey depends on its maximum torque, measured in the physical unit newton meters [Nm].

SEW modular system offers a complete range of germotors to meet the needs of your specific application:

- size and footprint

- power range

- gear ratio

- maximum torque

- drive configuration

- surface finish

- available in foot- or flange-mounted design

RX series helical gear units

High-efficicy helical gear unit for roller conveyors, chain conveyors or belt conveyors.

High-efficicy helical gear unit for roller conveyors, chain conveyors or belt conveyors.

- 6 frame sizes available

- available in foot- or flange-mounted design

Technical data

| Gear unit ratio | i | 1,30 – 8,65 |

| Max. output torque | Nm | 69 – 830 |

| Motor power range (Mounting via AM motor adapter) | kW | 0,12 – 45 |

R / RM series helical gear units (two and three stages)

Helical gear units with extended output bearing hub specifically designed for blending operations: agitators, blenders, mixers, kneaders.

- 10 sizes available

- Allowing for high overhung and axial loads as well as bending moments

Technical data

| Gear unit ratio | i | 4,29 – 289,74 |

| Double gear unit reduction ratio | i | 134 – 27 001 |

| Max. output torque | Nm | 450 – 18 000 |

| Motor power range (Mounting via AM motor adapter) | kW | 0,12 – 160 |

F series parallel-shaft helical gear units

The axis-parallel gear units have a slim design. Nonetheless, they offer a power range from 130 to 18,000 Nm. We think they are always a good choice when space is limited.

The axis-parallel gear units have a slim design. Nonetheless, they offer a power range from 130 to 18,000 Nm. We think they are always a good choice when space is limited.

- 11 frame sizes available, 27 to 157

- available in foot- , flange-mounted design or hollow-shaft or reduced backlash

Technical data

| Gear unit ratio | i | 3,77 – 281,71 |

| Double gear unit reduction ratio | i | 87 – 31 434 |

| Max. output torque | Nm | 130 – 18 000 |

| Motor power range (Mounting via AM motor adapter) | kW | 0,12 – 90 |

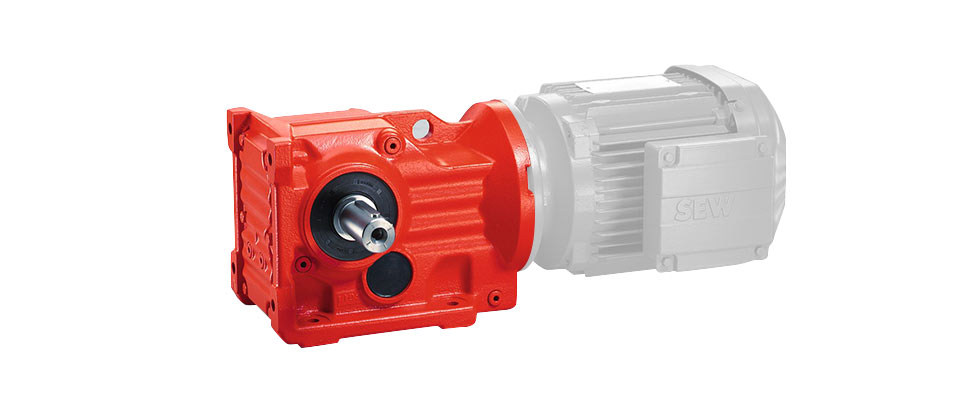

K series helical-bevel gear units

Powerful, compact right-angle gear units with a high level of efficiency. Their high-endurance gearing is maintenance-free operating life. These gear units are designed for applications such as conveyors, lifting devices and lifting stations, scissor lift tables, goods lifts, travel and hoist drives in stacker cranes.

Powerful, compact right-angle gear units with a high level of efficiency. Their high-endurance gearing is maintenance-free operating life. These gear units are designed for applications such as conveyors, lifting devices and lifting stations, scissor lift tables, goods lifts, travel and hoist drives in stacker cranes.

- 16 sizes available

- Max. output torque 80 Nm to 50 000 Nm

K series helical-bevel gear units – 3 levels

Sizes 37 / 47 / 57 / 67 / 77 / 87 / 97 / 107 / 127 / 157 / 167 / 187

Technical data

| Gear unit ratio | i | 3,98 – 197,37 |

| Double gear unit reduction ratio | i | 94 – 32 625 |

| Max. output torque | Nm | 200 – 50 000 |

| Motor power range (Mounting via AM motor adapter) | kW | 0,12 – 90 |

K series helical-bevel gear units – 2 levels

Sizes 19 / 29 / 39 / 49

Technical data

| K..19 | K..29 | K..39 | K..49 | ||

|---|---|---|---|---|---|

| Gear unit ratio | i | 4,50 – 58,68 | 3,19 – 71,93 | 42,81 – 58,24 | 4,0 – 75,20 |

| Max. output torque | Nm | 80 | 130 | 300 | 500 |

| Motor power range (Mounting via AM motor adapter) | kW | 0,12 – 1,1 | 0,12 – 2,2 | 0,12 – 4,0 | 0,12 – 7,5 |

S series helical-worm gear units

S series / Sizes 37 / 47 / 57 / 67 / 77 / 87 / 97

The combination with a helical gear stage significantly increases the efficiency compared to pure helical worm S series gear units. The linear power transmission makes the helical-worm gear units especially quiet in operation. Thanks to their performances, they suit to theater applications, infrequent speed variations, presses, rotary tables and corner transfer units.

The combination with a helical gear stage significantly increases the efficiency compared to pure helical worm S series gear units. The linear power transmission makes the helical-worm gear units especially quiet in operation. Thanks to their performances, they suit to theater applications, infrequent speed variations, presses, rotary tables and corner transfer units.

Technical data

| Gear unit ratio | i | 3,97 – 288,00 |

| Double gear unit reduction ratio | i | 110 – 33 818 |

| Max. output torque | Nm | 92 – 4 000 |

| Motor power range (Mounting via AM motor adapter) | kW | 0,12 – 30 |

SEW gearmotors mounting

Important: The mounting position is an essential parameter to be taken into account for the gear unit life service as it determines the required oil quantity in the gear unit. It is imperative the internal sprockets to be in contact with the oil (splash lubrication, oil bath).

Exemple :

- M1 mounting position (horizontal): gear unit filled with approx. ¼ oil

- M2 mounting position (vertical): gear unit filled with approx. ¾ oil

Series R gearmotors mounting position

Series F gearmotors mounting position

Series K / S / W gearmotors mounting position